H.I.P. Framework

Hybrid Intaglio Printing Framework or H.I.P. Framework

Dynamic market conditions, changing consumer behavior, vigorous timelines and enthusiastic marketing needs have altered the face of the Indian retail industry. New product launches are the need of the hour, and one size no longer fits all, propelling us towards inventiveness, speed and versatility in packaging.

The H.I.P. Framework was designed and perfected to tackle these growing packaging demands in ways that are quick, efficient and cost-effective. A powerful and robust system, it addresses the concerns of development costs, order quantities, time to market and value additions, through the innovative use of technologies.

“H.I.P. Framework is our USP. Method of production in flexible packaging, where the advantages of various printing technologies and software are intertwined together to achieve exceptional packaging solutions that meet urgent demands, minimizes development costs and offers never-seen-before ingenuity in print effects on shrink sleeves.”

Chetan Jain

Director- Taurus Packaging Pvt. Ltd.

Creator of H.I.P. Framework

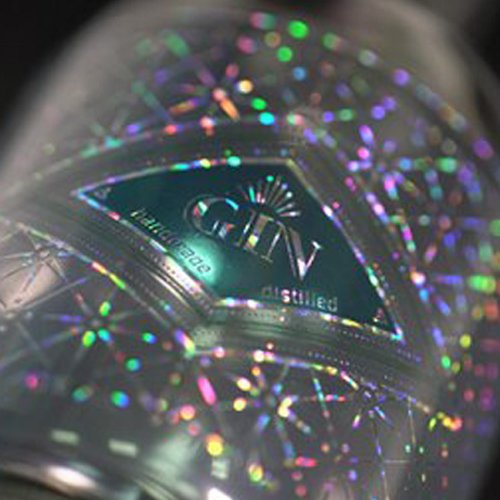

Maximizing Uniqueness Effectively: Hybrid Shrink Sleeves

The retail industry is more competitive than ever before. Customers are no longer easy to please, and brand clutter is a growing menace, pushing FMCG businesses towards finding newer ways to make their presence felt, be it new product launches or smart packaging. Hybrid Shrink Sleeves come to the rescue.

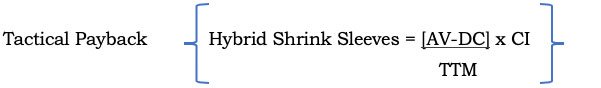

Developed using the H.I.P. Framework, Hybrid Shrink Sleeves creates an ‘Area of Action’ that removes limitations and magnifies effectiveness in product development. It reshuffles the equation of quantities, development investments, timelines and innovations, and makes the brands they represent highly memorable.

AV: Any Volume

DC: Development Cost

TTM: Time to Market

CI: Constant Innovation

“ Packaging is not just what it looks and feels like, packaging is how it works ”

Steve Jobs

Co-Founder of Apple Inc.

AREA OF ACTIVITY

Any-Volume Demand, Customer-Centric Design, Time-Bound Delivery

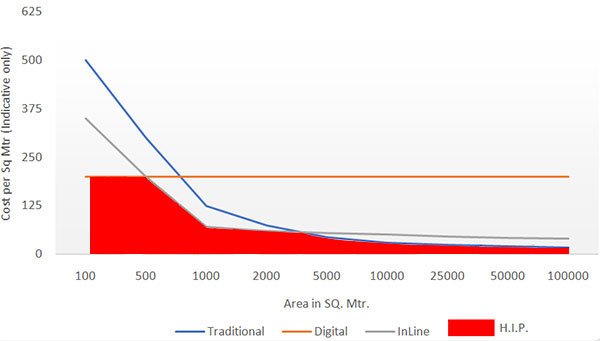

Present-day retail demands flexible packaging solutions that support new product launches, meet short quantity requirements at lightning speed and save hefty inventory costs. Time is money, and the right shrink sleeve can save us both.

Hybrid Shrink Sleeves stand out for their stellar design capabilities including exceptional special effects that turn an ordinary sleeve into one that catches the eye and influence sconsumer buying. Made with the end-customer in mind, it maximizes effectiveness in design, details and delivery while maintaining a firm grip on development costs, MOQ and timelines.

What you get, as a result, is the flexibility you are craving in packaging solutions, so you never run out of feasible options to meet your growing needs and exceed customer expectations.

A Strategic Amalgamation of Three Techniques

H.I.P. combines the advantages and strengths of three printing techniques, Flexo, Digital and Gravure into one advanced Shrink Sleeve product that makes frequent changes and corrections in design, easy and cheap. Not burdened by order quantities, it offers winning customer experiences.

Powered by the H.I.P. Framework, we look at the end goal holistically, innovate where possible, cut costs and meet any quantity requirements swiftly.