India’s No.1 Shrink Sleeve and Label Manufacturer

From innovation to sustainability, 3X your product

visibility with H.I.P. Framework based Shrink Sleeves.

From innovation to sustainability, 3X your product

visibility with H.I.P. Framework based Shrink Sleeves.

You’re not alone! Since 1994...

Most FMCG or CPG companies either struggle with world-class quality shrink sleeves or have a slow development pace and delayed deliveries.

At Taurus, we help you break free from these challenges.

With a large state-of-the-art manufacturing facility equipped with the most modern machines, we have a proven track record of:

Consistently delivering high-quality output

Fastest turnaround time in the industry

Global Expertise in shrink sleeves and more

One of the largest printing infrastructures in India

Partnering with Taurus proved to be a game-changer for us. Whether it's a small or bulk order, they consistently deliver on time without exceeding our budget.”

Adithan A.G.

(GM Packaging, The Himalaya Drug Co.)

A big thank you to Chetan and his team at Taurus for making our PETG packaging development successful.”

Ajay Rajvanshi

(Manager - Corporate Print Pkg Development, Nestle)

Elevate your packaging with innovation and precision, where every label tells a story

Powering brands across diverse industries

Years of Packaging Expertise

Customers Served

Labels Printed and Delivered

State-of-the-Art Manufacturing Units

Team Members Focused on Customers

On-Time Delivery

A team shaped by years of learning, experimentation, and real-world execution across industries.

We create innovative new product development that makes your brand stand out.

With our expertise, we guarantee shrink sleeve development in 50% less time and at 75% less cost.

With our offices across the globe, we make it easy for global brands to work seamlessly with us.

Rajesh and Chetan Jain – Torchbearers of a Legacy Built Over the Years

Hello,

As I reflect on Taurus’s journey, I feel immense pride and gratitude. What began as a small, passionate venture in Delhi has grown into a trusted global name in packaging.

For us, packaging isn’t just a product; it’s a promise of performance. Guided by our core values of innovation, reliability, sustainability, and teamwork, we’ve built lasting partnerships and a legacy of excellence.

We’ve grown from a regional player into an international leader, powered by world-class technology, sustainable materials, and continuous innovation. The H.I.P. Framework and recyclable materials like TruCycl and Floatabel reinforce our commitment to a future that blends performance with responsibility.

But the true strength of any organization lies in its people. I can proudly say that behind every milestone we’ve achieved, the Taurus team has played the defining role. Their passion fuels our progress and strengthens our mission to deliver shrink sleeve solutions that combine aesthetics, functionality, and sustainability.

As we look ahead, our goal remains simple: to grow responsibly, innovate relentlessly, and lead with purpose.

With gratitude,

(CEO & Managing Director)

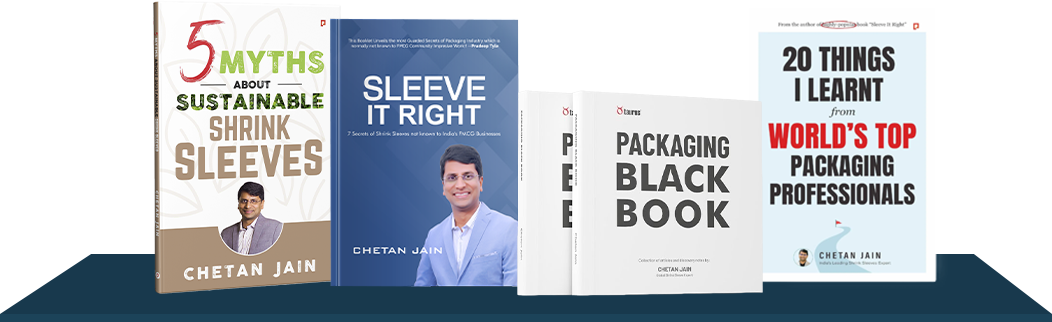

Chetan Jain has authored four insightful books, each crafted to empower the shrink sleeve industry and its stakeholders with real-world knowledge.

From busting myths around sustainability to sharing technical answers sought by top brands, these books are a must-read for anyone serious about mastering shrink sleeve packaging.

Explore how Chetan & team Taurus can add value to your requirements and find the best-fit solutions for your next project.

During this 20-minute discovery call, Chetan will:

You will also receive a collection of books written by Chetan, absolutely FREE.

Taurus is one of our leading vendors for packaging material.

Their exceptionally fast turn-around time, commitment and the ease with which they work under pressure make them stand out from others. ”

Arun Dey

(Purchase Manager - Dabur India Ltd)

We wanted short quantity, perfect print quality, picture-perfect shrink, no distortions, complete R&D and fastest timelines for our product. ”

It may sound too much, but Taurus got it all right and delivered! Cheers! ”

Pran Raj

(Director Supply Chain, Bira 91)

Powerful resources to help you gain valuable insights and stay ahead with innovation

“Great packaging isn’t just about aesthetics; it’s about

precision, innovation, and making every product stand out.”

Chetan Jain

Managing Director & CEO

Fill in your details and we’ll get back to you.

Get A Quote